In today’s world of the Industrial Internet of Things (iIoT), and Industry 4.0 programmable controllers are called upon to communicate data via Web browser, connect to databases via SQL, and even to the cloud data via MQTT.

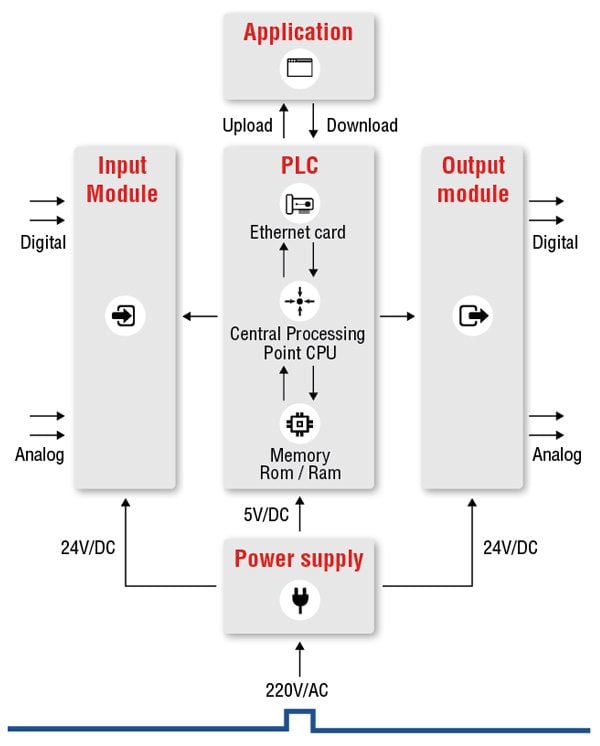

A Programmable Logic Controller, or PLC, is a ruggedized computer used for industrial automation. These controllers can automate a specific process, machine function, or even an entire production line.

In today’s world of the Industrial Internet of Things (iIoT), and Industry 4.0 programmable controllers are called upon to communicate data via Web browser, connect to databases via SQL, and even to the cloud data via MQTT.

An All-in-One PLC integrates the controller with the HMI panel, creating a compact, easy-to-use automation solution. Users no longer need to establish PLC to panel communications and can program both the Ladder Logic and HMI design in a single software environment. An all-in-one approach saves time, reduces wiring, and cuts the cost of purchasing multiple devices.

A PLC program is usually written on a computer and then is downloaded to the controller

Most PLC programming software offers programming in Ladder Logic, or “C”. Ladder Logic is the traditional programming language. It mimics circuit diagrams with “rungs” of logic read left to right. Each rung represents a specific action controlled by the PLC, starting with an input or series of inputs (contacts) that result in an output (coil). Because of its visual nature, Ladder Logic can be easier to implement than many other programming languages.

“C” programming is a more recent innovation.

Some PLC manufacturers supply control programming software.