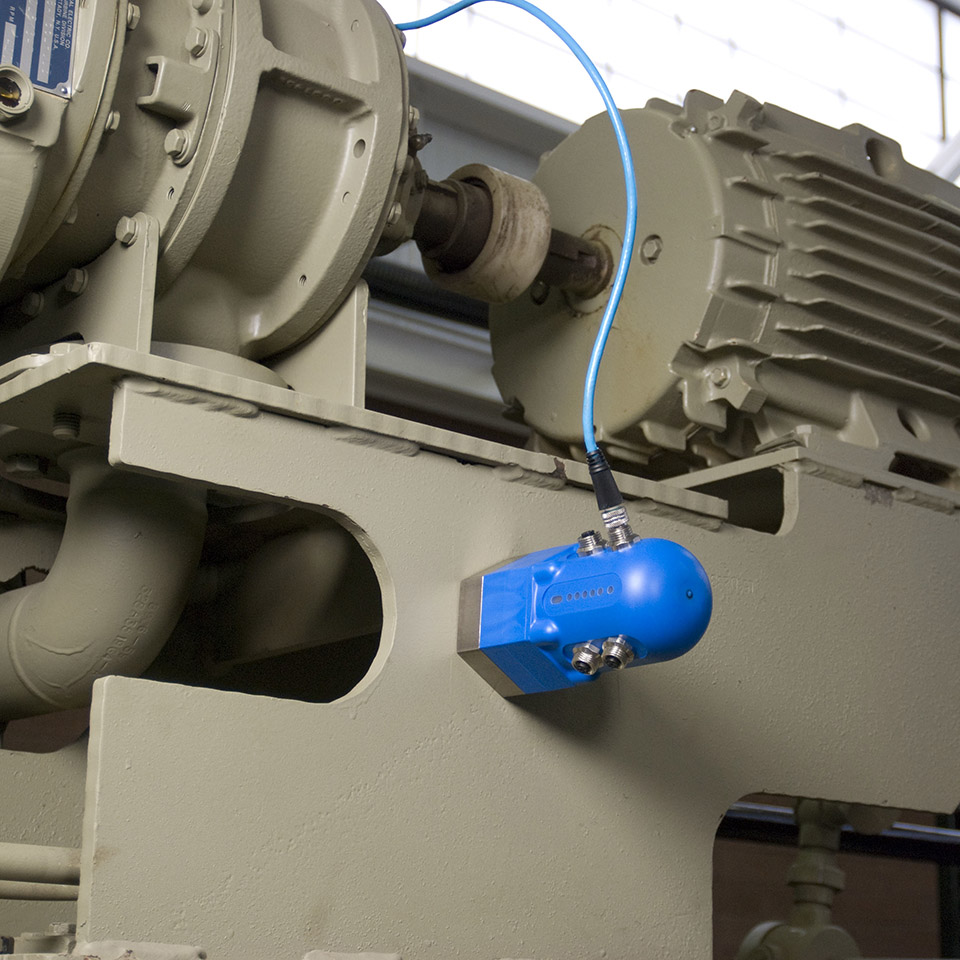

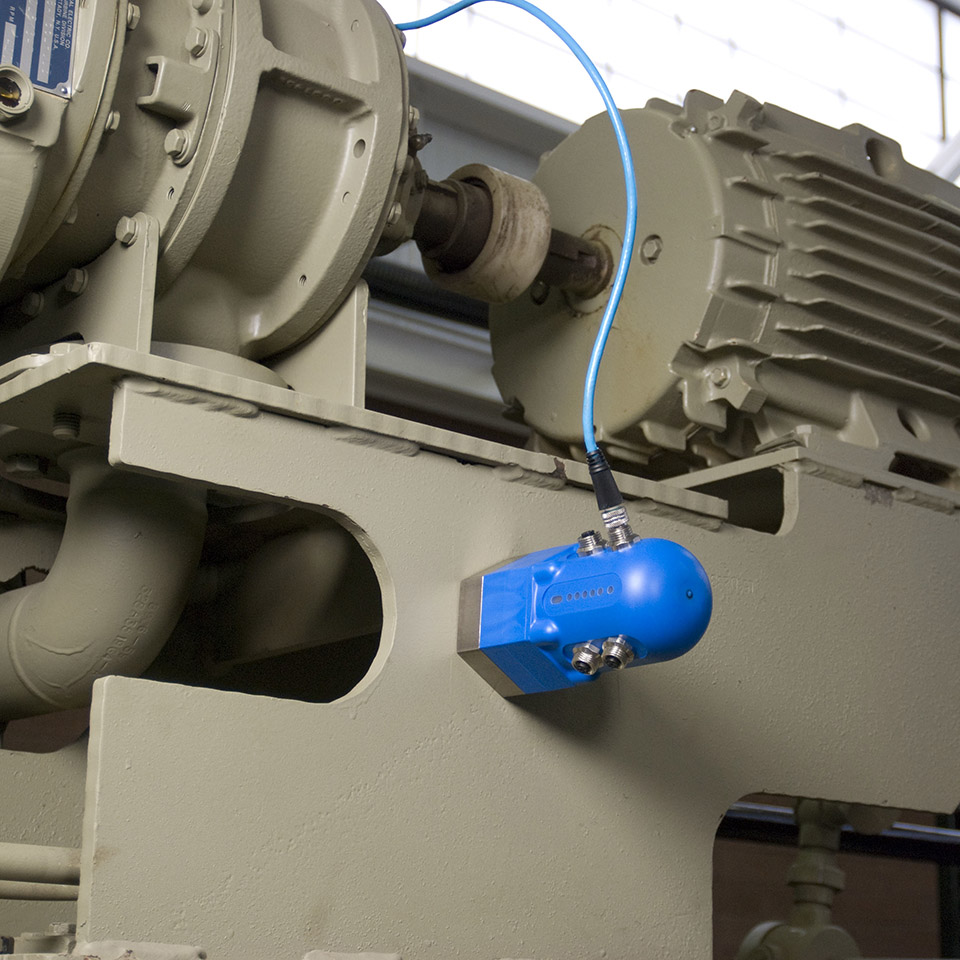

Bently Nevada 3500 vibration monitoring system

Mar 11,2022

The Bently Nevada 3500 Vibration Monitoring System reduces non-critical trips, including noise-driven and transient vibration shutdowns and nuisance vibration alarms/trips during start-up.

How we get you there

-

Virtually every aspect of the Bently Nevada 3500’s operation is software configurable, making it extremely flexible.

-

Easier spare parts management—a single module type can be configured for a variety of functions rather than just a single function.

-

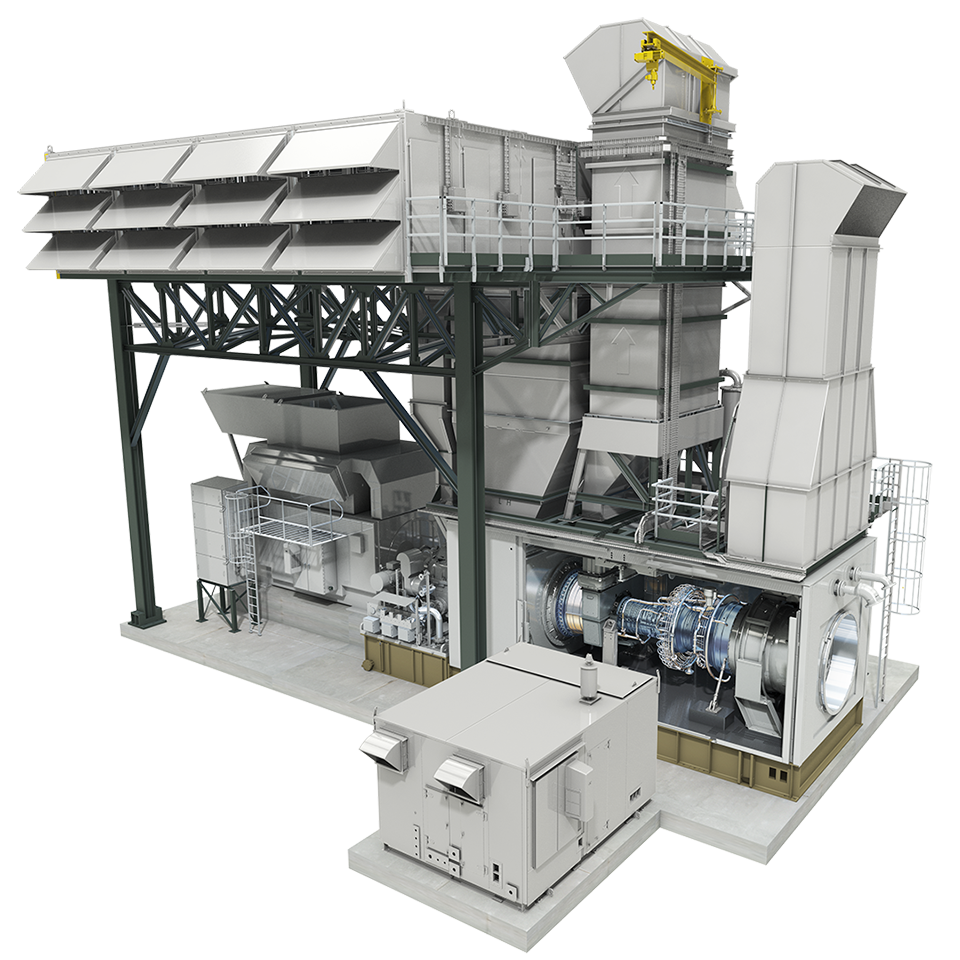

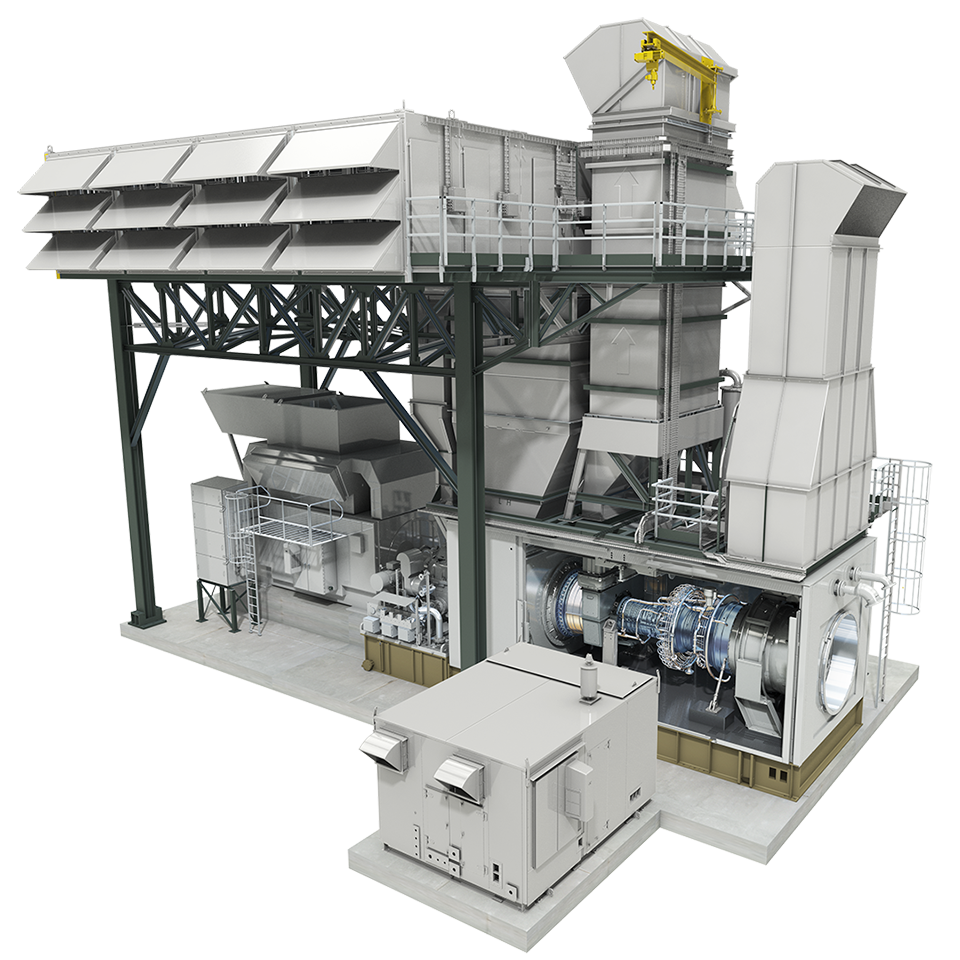

Communication between the gas turbine vibration monitoring system and the control system is Ethernet-enabled.

-

Reduces the number of recommended spare parts and support for customers with the BN7200.

-

Fits twice as many channels into the same rack space as previous vibration monitoring systems, resulting in lower installation costs by saving valuable cabinet space and spreading common components.

-

The Bently Nevada 3500 Vibration Monitoring System provides continuous, online vibration monitoring.

-

-

-

Condition-monitoring innovations

-

The upgrade includes a full-size 3500 Rack available in 19” EIA rail-mount, panel-cutout-mount, and bulkhead–mount versions.

-

The Rack Interface Module (RIM) is the primary interface to the Bently Nevada 3500’s configuration, display, and condition-monitoring software.

-

The 3500/15 power supply features line noise filters as standard and can be ordered for AC or DC input power, providing compatibility with voltage sources worldwide.

-

Individual alarm and danger settings and instantaneous amplitude readings are available for each function.

-

3500 information can be displayed by either of the following:

-

The existing HMI, requiring a software update

-

Provided Bently Nevada HMI with 3500/94 VGA Display (an option in BOM)