|

Manufacture |

Vibration |

|

Model |

TQ912 |

| PN No. |

204-900-000-011 |

|

Catalog |

S3960 |

|

Description |

proximity measurement chains |

| Origin | Swizerland |

| HS CODE |

85389091 |

| Dimension |

12*6*4 (CM) |

| Weight | 0.6 kg |

Description:

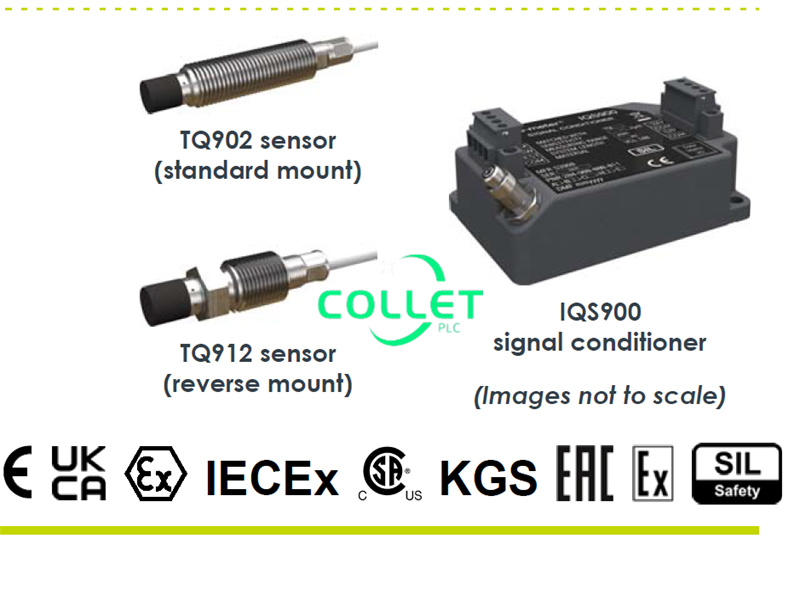

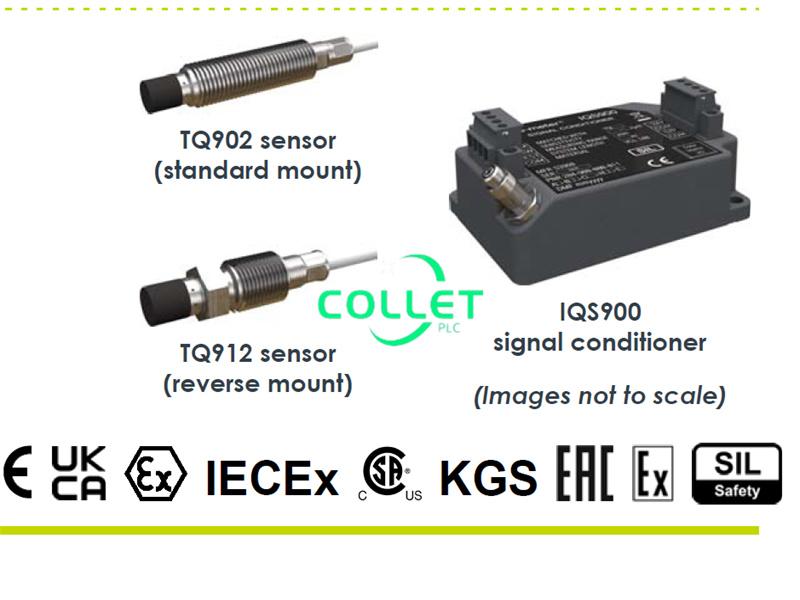

The TQ902/TQ912, EA902 and IQS900 form proximity measurement chains, from Meggitt’s vibro-meter® product line.

TQ9xx-based proximity measurement chains allow contactless measurement of the relative displacement of moving machine elements, and provide an output signal proportional to the distance between the sensor tip and the target. Accordingly, these measurement chains are ideally suited for measuring the relative vibration and axial position of rotating machine shafts, such as those found in steam, gas and hydraulic turbines, as well as in alternators, turbo-compressors and pumps.

A TQ9xx-based proximity measurement chain consists of a TQ9xx proximity sensor, an optional EA90x extension cable and an IQS900 signal conditioner, configured for a particular industrial application. The EA90x extension cable is used to effectively lengthen the front-end, as required. Together, these form a calibrated proximity measurement chain in which each component is interchangeable.

The IQS900 signal conditioner is a versatile and configurable device that performs all required signal processing and generates the output signal (current or voltage) for input to a machinery monitoring system such as a VM600Mk2/VM600 or VibroSmart®. In addition, the IQS900 supports optional diagnostic circuitry (that is, built-in self-test (BIST)) that automatically detects and remotely indicates problems with a measurement chain.

TQ902/TQ912 sensors and cabling

The active part of a TQ9xx proximity sensor is a coil of wire that is moulded inside the tip of the device, made of PPS (polyphenylene sulfide), a high-performance, high-temperature engineering thermoplastic. The sensor body is made of stainless steel. The target material must, in all cases, be metallic.

The TQ902 and TQ912 proximity sensors are essentially the same except that the TQ902 is intended for standard-mount and the TQ912 is for reverse-mount applications. Both sensor bodies are available with metric or imperial threads and have an integral coaxial cable terminated with a self-locking miniature coaxial connector. A TQ9xx sensor’s integral cable and the EA90x extension cables are available in various lengths, which can be combined to obtain a particular total system length (TSL) for an application.

Optional interconnection protectors (IP172), junction boxes (JB118) and other housings are available for the mechanical and environmental protection of the connection between a TQ9xx sensor’s integral cable and an EA90x extension cable.

IQS900 signal conditioner

The IQS900 signal conditioner contains a high-frequency modulator/demodulator that supplies a driving signal to a TQ9xx sensor. This generates an electromagnetic field in the tip of the sensor, which generates eddy-currents in the metallic target. When the target moves, the eddy-currents change, which causes a change in the electrical characteristics of the TQ9xx that the signal conditioner converts into a signal that is proportional to the distance to the target.

The IQS900’s output is an analogue signal consisting of a dynamic component (AC) that corresponds to the measured vibration (displacement) and a quasi-static component (DC) that corresponds to the measured gap. The output can be configured as a current or a voltage signal, suitable for transmission to a monitoring system via current (2-wire) or voltage (3-wire) transmission cables, respectively.

For an IQS900 signal conditioner with optional diagnostics, the quasi-static DC component also functions as a diagnostic indicator. That is, the IQS900’s diagnostic circuitry continuously checks the integrity of the measurement chain and will drive the measurement/diagnostic component (DC) outside of its normal operating range to indicate a problem with the sensor, the cabling and/or the signal conditioner itself.

For test purposes, the IQS900 includes a “raw” voltage output signal and a test input signal that allow the measurement chain/system operation to be tested in situ, thereby simplifying commissioning and troubleshooting.

Datasheet Link:

TQ912 Vibration 204-900-000-011 proximity measurement chains Datasheet

TQ912 Vibration 204-900-000-011 proximity measurement chains Datasheet