|

Manufacture |

Vibration |

|

Model |

EA403 |

| PN No. |

913-403-000-012 |

|

Catalog |

NIL |

|

Description |

extension cable |

| Origin |

Switzerland |

| HS CODE |

85389091 |

| Dimension |

30*23*8 (CM) |

| Weight | 1.2 kg |

Description:

This proximity system allows contactless

measurement of the relative displacement of moving

machine elements. It is particularly suitable for

measuring the axial position of rotating machine

shafts, such as those found in steam, gas and

hydraulic turbines, as well as in alternators, turbocompressors

and pumps.

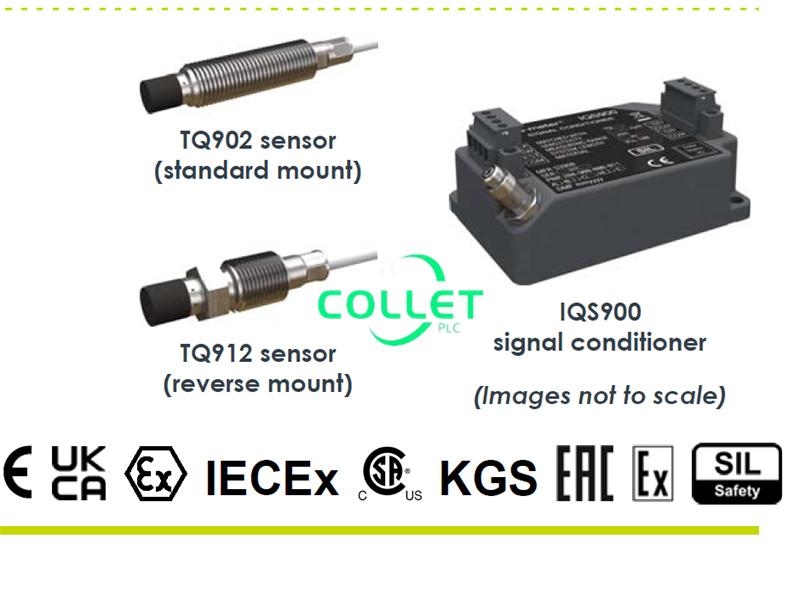

The system is based around a TQ 403 non-contact

transducer and an IQS 450 signal conditioner.

Together, these form a calibrated proximity system in

which each component is interchangeable. The

system outputs a voltage or current proportional to

the distance between the transducer tip and the

target, such as a machine shaft

The active part of the transducer is a coil of wire that

is moulded inside the tip of the device, made of

Torlon ® (polyamide-imide). The transducer body is

made of stainless steel. The target material must, in

all cases, be metallic.

The transducer body is available only with metric

thread. The TQ 403 has an integral coaxial cable,

terminated with a self-locking miniature coaxial

connector. Various cable lengths (integral and

extension) can be ordered.

The IQS 450 signal conditioner contains a highfrequency

modulator / demodulator that supplies a

driving signal to the transducer. This generates the

necessary electromagnetic field used to measure the

gap. The conditioner circuitry is made of high-quality

components and is mounted in an aluminium

extrusion.

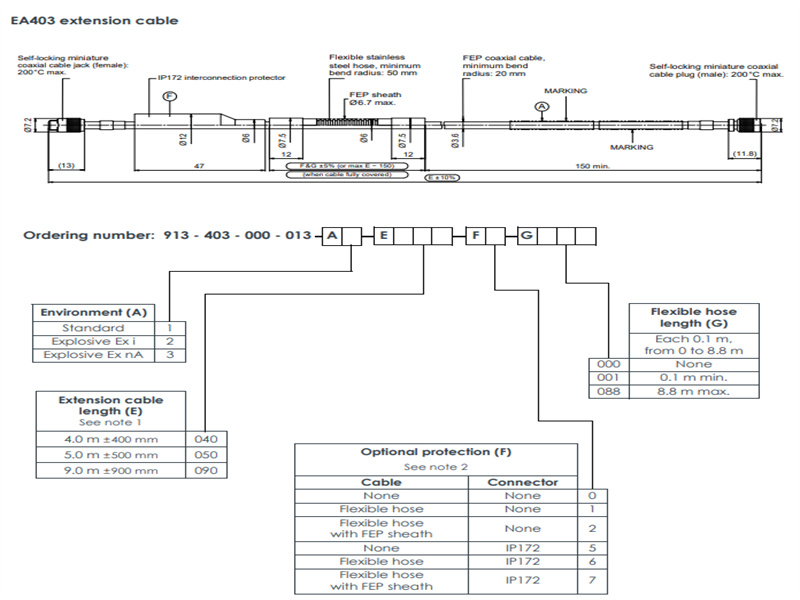

The TQ 403 transducer can be matched with a single

EA 403 extension cable to effectively lengthen the

front-end. extension cable to effectively lengthen the

front-end. Optional housings, junction boxes and

interconnection protectors are available for the

mechanical and environmental protection of the

connection between the integral and extension

cables.

The proximity system can be powered by associated

signal processing modules (for example, VM600

cards) or a rack power supply.

NEW AND ORIGIN ITEM IN STOCK

WITH ONE YEAR WARRANTY

Hope anyone enquire from us,pls click this sales6@nseauto.com

1. lower your support costs

2, Provide on-going availability of automation replacement parts

Quantity available: 1

Warranty: 12 months.

Lead time: 1-2 working days.

Terms of payment:T/T and Western Union.

Courier partners: DHL, UPS, TNT, FedEx and EMS.

Technical specification, manuals and data sheets

SPECIFICATIONS:

System calibration

Calibration temperature : +23 °C ± 5 °C

Target material : VCL 140 steel (1.7225)

Note: If special calibration is required, please define the alloy precisely or supply a sample of alloy (min. Ø 60 mm /

1 cm thick) according to Meggitt Sensing Systems’ drawing number PZ 7009/1.

Total system length

The total system length (TSL) is the sum of the length of the TQ 4xx transducer’s integral cable and the length of the

EA 40x extension cable. The supported TSLs can be obtained from different combinations of cables.

Total system lengths

• 5 m : 1.0 m integral cable + 4.0 m extension cable

5.0 m integral cable with no extension cable

• 10 m : 1.0 m integral cable + 9.0 m extension cable

5.0 m integral cable + 5.0 m extension cable

10.0 m integral cable with no extension cable

The combination of cables selected for a particular total system length depends on the application. For example, to

obtain the optimum location for the separation between the integral and extension cables or to eliminate the

requirement for an extension cable.

Total system length trimming

Due to the characteristics of the coaxial cable, an "electrical trimming" of the nominal length of extension cables is

necessary to optimize the system performance and the transducer interchangeability.

TSL for a 5 m measuring chain : 4.4 m minimum

TSL for a 10 m measuring chain : 8.8 m minimum